Whether you’re a seasoned seamstress or just starting out, encountering sewing problems is inevitable. From thread tension issues to needle breakage, sewing machine issues can cause frustration and impact the outcome of your project. Fortunately, you can troubleshoot and overcome common sewing problems with the right tips and techniques.

In this comprehensive guide to sewing troubleshooting solutions, you’ll learn from expert seamstresses how to identify and resolve common sewing machine issues. From thread tension problems to bobbin winding and needle-related issues, you’ll gain the knowledge and skills necessary to tackle any sewing challenge.

So, sit back, relax, and get ready to become a sewing troubleshooting pro!

- Identifying common sewing issues is the first step in troubleshooting.

- Proper maintenance is essential for optimal sewing machine performance.

- Thread and stitching problems can cause frustration, but there are solutions.

- Understanding bobbin winding and needle-related issues can improve your sewing results.

- Mastering sewing techniques through tips and tricks can elevate your skills to the next level.

Here is your requested text for section 2:

Understanding Common Sewing Machine Problems

As a sewist, you will likely encounter some common sewing machine problems occasionally. It’s important to understand the causes of these issues and how to troubleshoot them so you can get back to your project with minimal interruption.

One of the most frequent sewing machine issues is thread tension problems. When your tension is off, you may experience loose or tight stitches that affect the overall quality of your sewing. To troubleshoot, start by checking that your thread is properly threaded through all the necessary guides and the tension discs. Then, adjust your upper tension as necessary, making small changes until you achieve the desired stitch quality.

Another common issue sewists face is needle breakage. This can be caused by using the wrong needle for your fabric, a dull or bent needle, or incorrect machine settings. To avoid needle breakage, make sure to choose the right size and type of needle for your fabric, replace your needles regularly, and check your machine settings before beginning your project.

Uneven stitches can also be a problem, but this is often due to incorrect timing or poor maintenance of your machine. If you notice uneven stitches, it may be time to take your machine in for a tune-up and cleaning.

Regardless of the issue, the key is to remain calm and methodical in your troubleshooting. Take the time to assess the situation and make adjustments as necessary to get your machine running smoothly again.

When you encounter sewing issues, don’t get discouraged. With a bit of patience and practice, you can become a skilled troubleshooter and keep your machine running smoothly for years to come.

Maintaining Your Sewing Machine for Optimal Performance

Your sewing machine is an essential tool for your sewing projects, and proper maintenance is essential for its optimal performance. Here are some tips on how to keep your machine in top shape:

| Task | Frequency |

|---|---|

| Cleaning | After every project or at least once a month |

| Lubricating | Every 3-6 months or according to manufacturer’s instructions |

| Checking for wear and tear | Every 6 months or before starting a big project |

When cleaning your sewing machine, be sure to remove any lint, dust, and debris from the bobbin area, feed dogs, and other components. You can use a small brush, compressed air, or a vacuum cleaner for this task. Always follow the manufacturer’s instructions for lubricating your machine, and use only high-quality sewing machine oil. Checking for wear and tear includes inspecting the needle, thread, and bobbin, as well as other parts of the machine, such as the belt and motor. If you notice any signs of damage or wear, it may be time for sewing machine repairs.

Regular maintenance can prevent sewing machine issues and ensure that your machine operates smoothly and reliably. If you’re not comfortable performing routine maintenance tasks, consider taking your machine to a professional for cleaning and sewing machine repairs. By maintaining your sewing machine, you’ll extend its lifespan and enjoy better results from your sewing projects.

Troubleshooting Thread Issues

Thread-related problems can be frustrating, but with the right troubleshooting techniques, you can overcome them. Here are some common thread issues and solutions to resolve them:

Thread Tension

Inconsistent thread tension can result in uneven stitches, thread breakage, or even fabric damage. To resolve this issue:

- Check the thread spool for any tangles or knots.

- Ensure that the thread is properly threaded through the machine, including the tension disks and take-up lever.

- Adjust the tension setting to a lower or higher number, depending on the fabric type.

- Use the same thread type for both the top and bobbin threads.

If the problem persists, consider getting your sewing machine professionally serviced.

Thread Breakage

A broken thread can be caused by various reasons, such as:

- A damaged or bent needle

- Incorrect thread tension

- Using the wrong needle for the fabric type

- Old or low-quality thread

To troubleshoot and fix thread breakage:

- Check the needle for any damage. Replace it if necessary.

- Ensure proper thread tension and thread path through the machine.

- Use the correct needle size and type for your fabric.

- Use high-quality thread.

Thread Bunching

Bunched-up thread under your fabric can result in unsightly and uneven stitches. To prevent thread bunching:

- Re-thread the machine, ensuring that the bobbin is correctly wound and inserted.

- Clean the machine and remove any lint or thread build-up.

- Ensure that the needle is the correct size and type for the fabric.

- Adjust the thread tension if needed.

- Slow down your stitching, as sewing too quickly can cause tension issues.

By following these solutions, you can tackle thread-related issues and enjoy a smooth sewing experience.

Stitching problems can be frustrating, but fortunately, they can be resolved with the right techniques. Here are some common stitching issues you might encounter and tips on how to fix them:

- Skipped stitches: Skipped stitches occur when your machine fails to catch the thread on a stitch. This problem can be caused by a dull needle, a bent needle, or incorrect threading. To fix this, try changing your hand and checking if your machine is threaded correctly.

- Uneven stitches: Uneven stitches can be caused by a variety of factors, such as incorrect tension or using the wrong needle. To adjust tension, refer to your sewing machine manual and test sew-on scraps until you get the right setting. Also, make sure you’re using the correct needle for your fabric type and thickness.

- Puckering: Puckering occurs when your fabric bunches up while sewing. This is often caused by incorrect tension, using the wrong needle, or poorly aligned fabric layers. To fix this problem, adjust your machine’s tension, select the right needle, and make sure your fabric layers are properly aligned.

Don’t let stitching problems discourage you! With a little patience and these tips, you’ll be able to overcome any obstacles and achieve the perfect stitches for your sewing projects.

Dealing with Bobbin Winding and Bobbin Thread Issues

Bobbin winding and bobbin thread issues can be frustrating and affect the smooth operation of your sewing machine. Here are some common bobbin issues and their solutions.

Bobbin Winding

When winding a bobbin, it’s essential to do it correctly. If the bobbin isn’t wound properly, it can cause issues such as thread breakage and tangling. Here are some tips for winding a bobbin:

- Wind the thread evenly and tightly around the bobbin.

- Make sure the thread is guided correctly through the bobbin winding path and tension disks.

- Don’t overfill the bobbin.

If you continue to experience issues with bobbin winding, consulting your sewing machine manual might be helpful.

Bobbin Thread Tension

When the bobbin thread tension is too tight or too loose, it can cause issues with the quality of your stitching. Here’s how to adjust the tension:

- Refer to your sewing machine manual for instructions on how to adjust the bobbin thread tension.

- Use a scrap piece of fabric to test the tension. If the tension is too tight, the stitches will be puckered. If the tension is too loose, you’ll see loops on the back of the fabric.

- Make small adjustments to the tension, testing with each adjustment until you achieve the desired results.

Bobbin Thread Breakage

Bobbin thread breakage can be caused by a variety of factors, such as incorrect threading, a faulty bobbin case, or a worn-out needle. Here’s how to prevent breakage:

- Make sure the bobbin is properly threaded and inserted into the bobbin case.

- Replace the bobbin case if it’s damaged or worn out.

- Make sure you’re using the correct needle size and type for your fabric. A worn-out needle can cause the bobbin thread to break.

By following these tips, you can troubleshoot and resolve bobbin winding and bobbin thread issues. Don’t let these common sewing problems slow you down!

Solving Needle-related Problems

Needle problems can be one of the most frustrating issues experienced by sewers, but fortunately, many of them can be easily resolved. Here are some common needle-related problems and solutions:

Needle Breakage

If your needle keeps breaking, first check to ensure it’s inserted correctly, as a needle that’s not inserted properly can easily snap. If it’s inserted correctly, it may be because the needle is too thin or thick for your fabric. For example, thin needles work better with lightweight fabrics, whereas thicker needles are better suited for heavyweight fabrics. Also, check if you’re using the appropriate needle for your sewing task. When in doubt, consult your sewing machine manual for needle recommendations.

Needle Threading

Threading a needle can be difficult, especially for those with poor eyesight. To make threading a needle easier, try using a needle threader. If a threader is not available, use a white piece of paper behind the needle to make the eye more visible. Additionally, ensure that your needle is not bent, damaged, or rusty, as a damaged needle can make threading difficult.

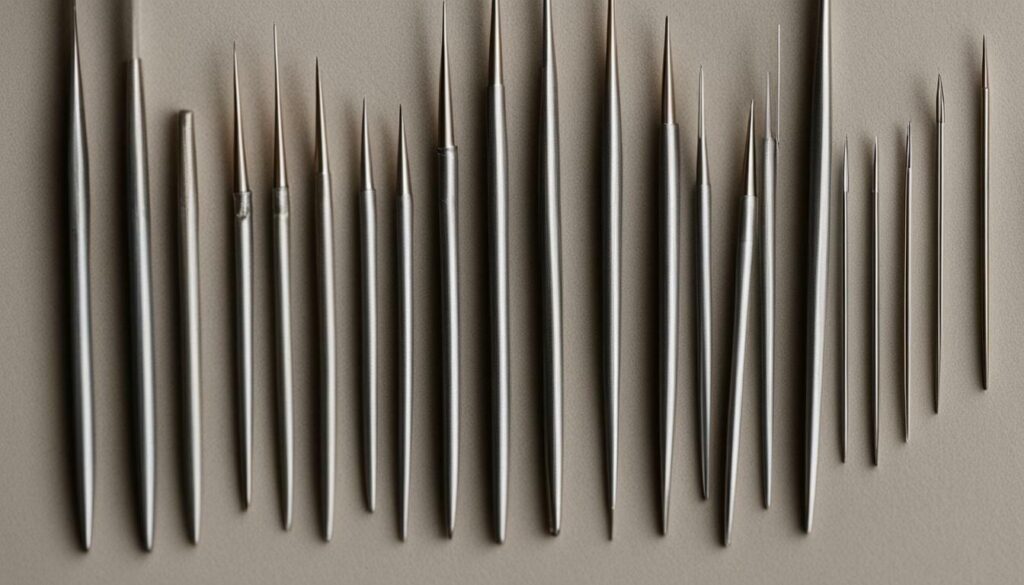

Needle Selection

Choosing the right needle for your fabric is crucial for achieving a professional-looking finish. Needles come in a variety of sizes and styles, and selecting the right one for your project can make all the difference. As a general rule, the thinner the fabric, the smaller the needle size should be. You should also consider the fabric type, as certain fabrics such as denim or leather, require a specific type of needle. Always refer to your sewing machine manual for needle recommendations.

With these solutions, you can overcome needle-related problems and enjoy a smooth sewing experience. But don’t forget that needles can also become dull with use, so it’s important to regularly replace your needle to ensure optimal sewing performance.

Now that you’ve tackled common sewing problems, it’s time to take your skills to the next level! Here are some expert tips and tricks to help you enhance your sewing techniques:

- Practice, practice, practice! The more you sew, the better you’ll get. Set aside time to practice new techniques and experiment with different fabrics and patterns.

- Invest in quality tools. Good quality tools can make a big difference in your sewing experience. Consider upgrading your scissors, rotary cutter, thread, and needles to high-quality options.

- Use a seam guide. A seam guide is a useful tool for achieving accurate seam allowances. You can purchase a seam guide or use washi tape as a temporary guide.

- Clip curves and corners. Clips are a great alternative to cutting notches and help to prevent fraying and bulk. Use them to clip curves and corners when sewing garments or other curved pieces.

- Press as you go. Pressing your seams as you sew helps to achieve crisp and professional-looking results. Use a good quality iron and press cloth to avoid damaging your fabric.

- Try different stitch types. Experiment with different stitch types, such as zigzag or stretch stitches, to achieve different effects and enhance the durability of your garments.

By incorporating these tips and tricks into your sewing routine, you’ll be on your way to mastering new techniques and achieving better results.

Thank you for reading our ultimate guide to sewing troubleshooting solutions! We hope that you found our expert tips and practical solutions helpful in overcoming common sewing problems and machine issues. Armed with this knowledge, you’ll be able to tackle any sewing challenge that comes your way.

Remember, proper maintenance of your sewing machine is key to its optimal performance. By keeping up with routine maintenance tasks and addressing issues as they arise, you’ll be able to avoid costly repairs in the future.

Keep Learning and Improving

As with any skill, practice makes perfect. The more you sew, the more familiar you’ll become with your machine, and the better your results will be. Don’t be afraid to experiment with new fabrics and techniques, and continue to seek out resources and advice to improve your sewing skills.

We hope that our guide has given you the confidence and tools you need to take your sewing to the next level. Happy sewing from all of us!

FAQ

What are some common sewing machine problems?

Some common sewing machine problems include thread tension issues, needle breakage, and thread bunching.

How can I maintain my sewing machine for optimal performance?

To maintain your sewing machine for optimal performance, make sure to clean and lubricate it regularly, as well as check for any signs of wear and tear. It’s also important to know when to seek professional sewing machine repairs.

How can I troubleshoot thread issues?

When it comes to thread issues, adjusting thread tension, selecting the right thread for your project, and avoiding common thread-related sewing problems can help resolve the issues you may encounter.

What can I do to resolve stitching problems?

To resolve stitching problems, such as skipped stitches, uneven stitches, and puckering, you can adjust your machine settings, choose the right needle, and effectively troubleshoot stitching issues.

How can I deal with bobbin winding and bobbin thread issues?

When facing bobbin winding and bobbin thread issues, troubleshooting techniques such as proper winding, adjusting bobbin thread tension, and resolving bobbin thread breakage can help maintain a consistent and reliable bobbin function.

What should I do if I encounter needle-related problems?

If you encounter needle-related problems, such as needle breakage, difficulty in threading needles, or choosing the right needle for your fabric, understanding the issues and implementing the suggested solutions can minimize disruptions and improve your sewing results.

Are there any tips and tricks to enhance my sewing techniques?

Yes, there are! Mastering sewing techniques can significantly improve your sewing experience. From handling tricky fabrics to mastering precise seams, implementing valuable tips and tricks can elevate your sewing skills to the next level.